Features

- Low cost

- Accommodates 40º misalignment

- High torque – 8 ft/lbs. with set screws. (30 ft/lbs. with keys or pins)

- Long life

- Any diameter inside bore up to 7/16 Inch Dia.

Applications

For manual or medium duty usage such as multi-spindles, farm equipment, conveyors, process machinery, snow throwers and other equipment.

Any other bore size available (including metric) promptly at no extra charge.

Designed for use with wide-angle power or control applications with angular misalignment up to 40º. The heart of the UNIMITE™ Universal coupling is the steel ball – a precision ball bearing. Hardened and ground dowel pins transmit high torque. Solid construction assures long life 2 Inch long x 5/8 Inch (5.08 x 15.9 mm) dia. with 4 set screws. Keyways available at extra cost.

Specifications

| Bore Diameter | 0.1875 Inch 4.76 mm |

|---|---|

| High Torque | 8 ft/lb |

| Inside Bore Diameter | 7/16 Inch |

| Misalignment | 40 º |

Why Our Couplings are Better

The function of every flexible coupling is to transmit power or motion control from one rotating shaft to another that is not perfectly aligned, without excessive bearing loads.

But since the requirements for transmitting power are not the same as they are for controlling motion, couplings designed to transmit power might well be unsuitable for motion control and vice versa.

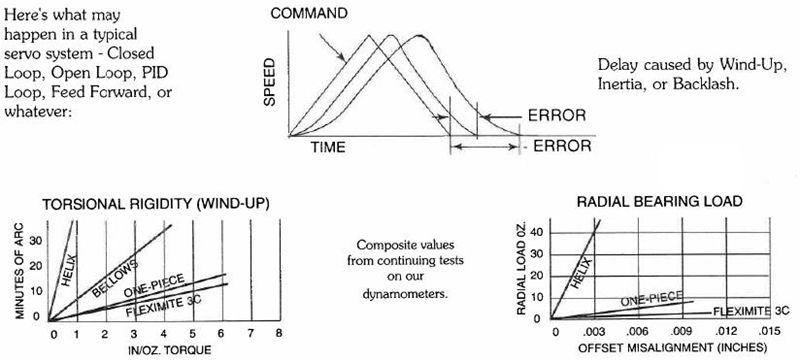

For instance, a resilient coupling made with rubber or springs would work well delivering power because it could absorb vibration and/or shock loads, but would not work well controlling motion. Here’s why: In a motion control system, every component in the drive train (including couplings) affects the accuracy of the system by the amount of compliance (Wind-Up), Inertia, Friction, Backlash, etc. – things quite unimportant when transmitting power. A coupling that absorbs vibration must by definition, have Wind-Up, Inertia, or Backlash; whereas a true-motion control coupling must have no Backlash, low Inertia, and very low Wind-Up.

There are many applications, which are extremely sensitive to these factors. Today’s encoders, for instance, can discriminate down to a few seconds of arc. (That’s the width of a dime seen from 2 miles away) So you see how couplings can affect the success of your design.

Torsional Wind-Up is a very important factor. Notice in the graphs how outstanding RENBRANDT Couplings are.

Other manufacturers offer similar misalignment accommodation and low compliance – BUT NOT IN THE SAME PRODUCT.

The system must also be free from imbalance, vibration, and oscillation in order to prevent hunting – especially in closed-loop systems where a null balance is established between error signals. Since 1951 RENBRANDT has been building and improving Servo Couplings that provide reliability and long life free from maintenance – at moderate cost.

Sizes/Part Numbers

| Item # | Bore Diameter | High Torque | Inside Bore Diameter | Misalignment |

|---|---|---|---|---|

| A-600-1 | 0.1875 Inch 4.76 mm |

8 ft/lb | 7/16 Inch | 40 º |

| A-600-2 | 0.25 Inch 6.35 mm |

8 ft/lb | 7/16 Inch | 40 º |

| A-600-3 | 0.3125 Inch 7.94 mm |

8 ft/lb | 7/16 Inch | 40 º |

| A-600-4 | 0.375 Inch 9.53 mm |

8 ft/lb | 7/16 Inch | 40 º |

| A-600-5 | 0.4375 Inch 11.11 mm |

8 ft/lb | 7/16 Inch | 40 º |

MADE IN THE USA

MADE IN THE USA